Easy-to-Apply Hand

Pallet Wrap

Our elastic, easy-to-apply hand pallet stretch wrap is perfect for protecting small loads during shipping, storage, and processing. For maximum stability and convenience, you can rely on us to deliver.

For bulk orders

To place an order

Our Hand Pallet Wrapping Products

Secure your goods with our versatile hand pallet wrap, designed for effortless application and reliable protection. Offering flexibility and strength, it ensures stable, damage-free shipments, safeguarding your business reputation while streamlining your packing processes with ease.

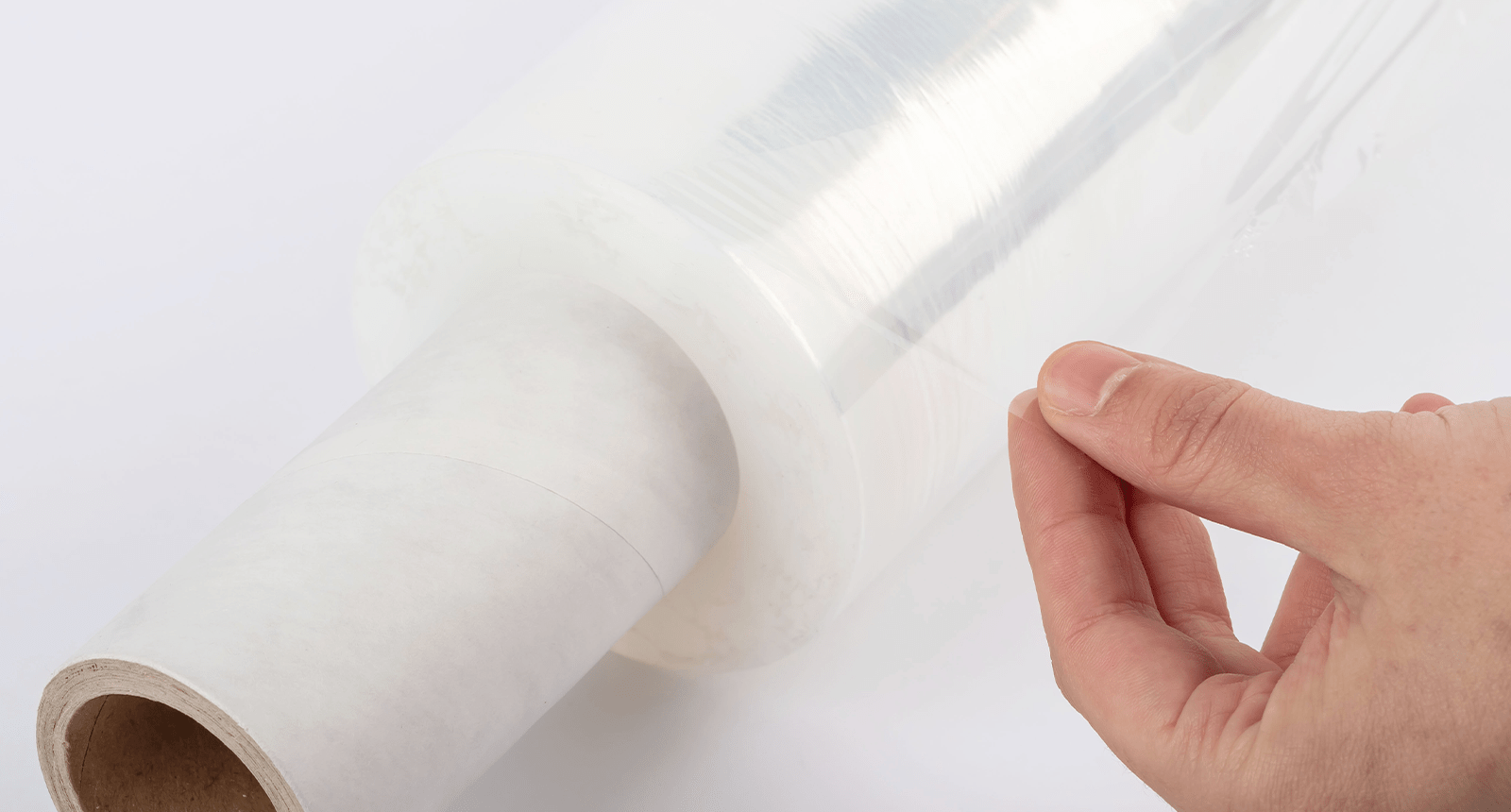

CLEAR HAND PALLET WRAP

Our clear hand pallet wrap delivers crystal-clear visibility for easy load identification. Its strong cling and durability protect goods from dust and moisture, ensuring stable, secure pallets that arrive intact.

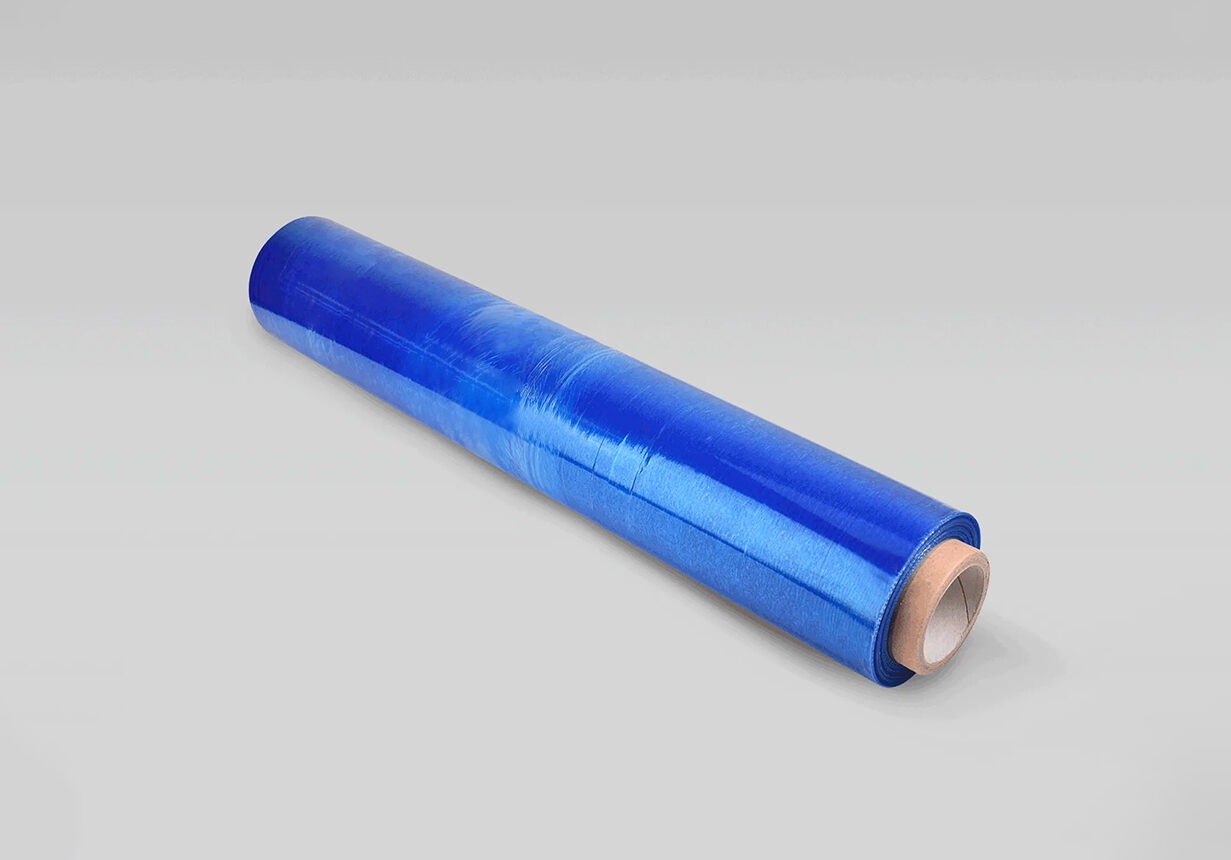

BLUE-TINT PALLET WRAP

Blue-tint hand pallet wrap adds a layer of UV protection, shielding goods from sun damage. Its robust hold ensures pallet stability, while the tinted design aids quick identification, keeping your shipments secure.

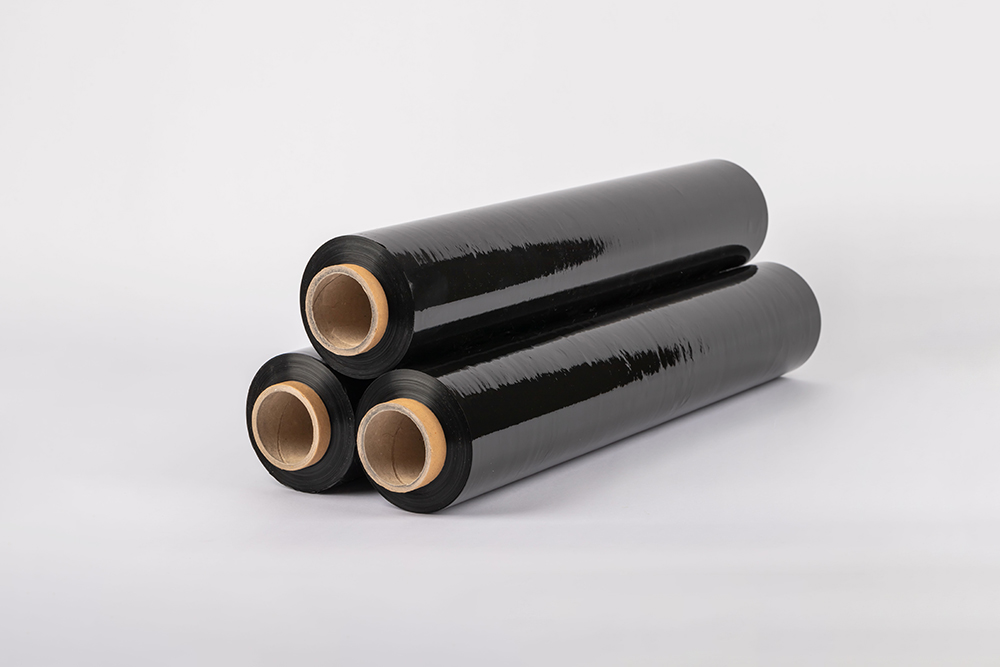

BLACK PALLET WRAP

Black hand pallet wrap offers maximum security, concealing valuable loads from prying eyes. Its tough, tear-resistant film guarantees stability and protection against contaminants.

Secure your free sample of premium hand pallet wrap today by

completing a contact form.

Hand Pallet Wrap Cores

Our hand pallet wrap options deliver unmatched flexibility and strength, ensuring secure, stable shipments. There are generally three core types available:

EXTENDED CORE PALLET WRAP

Extended core pallet wrap simplifies application with built-in handles, boosting efficiency. Its durable, high-cling film ensures pallet stability, protecting goods from moisture and dust, making it ideal for fast, secure wrapping without compromising reliability or strength.

FLUSH CORE

PALLET WRAP

Flush core pallet wrapping offers a sleek, dispenser-compatible design for smooth application. Its tough, tear-resistant film guarantees load stability and shields against contaminants, ensuring safe deliveries while optimising your packing process with professional, dependable results.

MINI PALLET

WRAP

Mini pallet wrap is ideal for small, irregular loads, offering precise wrapping control. Its strong cling and compact size ensure secure, stable bundles, protecting against damage whilst boosting speed and efficiency when you have small packages to wrap.

Our Hand Pallet Wrap Product Details

We have a range of hand pallet stretch wrap options to choose from, each with its own unique specifications and benefits.

| SKU | Type | Colour | Thickness | Film Width | Weight (Kg) | Product Description | Roll per Case | Case per Pallet |

|---|---|---|---|---|---|---|---|---|

| BTPW14 | Hand Roll | Blue | 14 mu | 400mm | - | 14 mu x 400 mm Ext Core BlueTint Hand Stretch Wrap | 6 | 64 |

| BTPW17 | Hand Roll | Blue | 17 mu | 400mm | - | 17 mu x 400 mm Ext Core Blue Tint Hand Stretch Wrap | 6 | 64 |

| PSFB502320 | Hand Roll | Black | 23 mu | 500mm | 2.42 | 500mmx23mux200m Flush Core Black Stretch Wrap 2.42 kg | 6 | 64 |

| PSHB502316 | Hand Roll | Black | 23 mu | 500mm | 1.6 | 500mm 23mu Black Hand Stretch Wrap 1.6 kg | 6 | 64 |

| PSHE401720 | Hand Roll | Clear | 17 mu | 400mm | - | 400mm 17mu 200m Ext Core Clear Stretch Wrap | 6 | 64 |

| PWT17500 | Hand Roll | Clear | 17 mu | 400mm | 1.5 | 17 mu x 400 mm Ext Core Clear Very Tacky Stretch Wrap 1.5kg | 6 | 64 |

| PWT32500 | Hand Roll | Clear | 32 mu | 400mm | 1.5 | 32 mu x 400 mm Ext Core Clear Very Tacky Stretch Wrap 1.5kg | 6 | 64 |

| PWT32700 | Hand Roll | Clear | 32 mu | 400mm | 1.7 | 32 mu x 400 mm Ext Core Clear Very Tacky Stretch Wrap 1.7kg | 6 | 64 |

| PWT20500 | Hand Roll | Clear | 20 mu | 400mm | 1.5 | 20 mu x 400 mm Ext Core Clear Very Tacky Stretch Wrap 1.5kg | 6 | 64 |

| PWT20700 | Hand Roll | Clear | 20 mu | 400mm | 1.7 | 20 mu x 400 mm Ext Core Clear Very Tacky Stretch Wrap 1.7 kg | 6 | 64 |

| PWTBO20500 | Hand Roll | Black | 20 mu | 400mm | 1.5 | 20 mu x 400 mm Ext Core Black Opaque Tacky Stretch Wrap 1.5 kg | 6 | 64 |

| PWTBO32500 | Hand Roll | Black | 32 mu | 400mm | 1.5 | 32 mu x 400 mm Ext Core Black Opaque Very Tacky Stretch Wrap 1.5 kg | 6 | 64 |

| PWTSBO255008 | Hand Roll | Black | 25 mu | 500mm | 1.8 | 25 mu x 500 mm Ext Core Black Opaque Very Tacky Stretch Wrap 1.8 kg | 6 | 64 |

| PWTSBO25700 | Hand Roll | Black | 25 mu | 400mm | 1.7 | 25 mu x 400 mm Ext Core Black Opaque Very Tacky Stretch Wrap 1.7 kg | 6 | 64 |

| PWT12 | Hand Roll | Clear | 12 mu | 400mm | - | 12 mu x 400 mm x 250m Ext Core Clear Very Tacky Stretch Wrap | 6 | 64 |

The Benefits of Manual Pallet Wrapping

Is manual pallet wrapping the right choice for your business? If you deal with relatively small, lightweight loads, hand pallet wrap can deliver a range of benefits.

Hand pallet wrap allows precise application, ideal for irregularly shaped or smaller loads. Operators can adjust tension and coverage on the spot.

Requiring no machinery, hand wrapping reduces equipment costs and maintenance. It’s perfect for small-to-medium businesses or operations with varied pallet sizes.

Hand pallet wrap is simple to use, speeding up packing processes. With options like extended core handles, it boosts efficiency, letting staff secure pallets in seconds without compromising strength or reliability.

High-cling, durable hand pallet wrap shields goods from moisture, dust, and transit damage. It ensures loads remain intact, safeguarding both your products and your reputation.

Lightweight and portable, hand pallet wrapping can be used anywhere in your warehouse or facility, offering versatility for businesses with dynamic packing needs or limited space.

Our recyclable hand pallet wrap helps businesses meet sustainability goals, protecting the environment whilst maintaining the robust performance needed for secure, stable shipments.

Why Choose Our Hand Pallet Wrap Products?

Our hand pallet wrap ensures secure, stable loads with strength and flexibility. It protects goods, streamlines packing, and upholds your reputation for reliable, efficient deliveries.

Water-Resistant

Our water-resistant hand pallet wrap protects goods from moisture, ensuring secure pallets. Its strong cling safeguards products and reputation, maintaining quality during transit or storage.

Durable

Our durable hand pallet wrap resists tears, ensuring stable pallets. It protects goods during tough journeys, minimising damage and ensuring reliable, intact shipments every time.

Easy to Apply

These premium products can be applied effortlessly, saving time and effort. Wrapping products with our hand pallet wrapping couldn’t be easier.

Clear and Coloured Options

Clear or coloured hand pallet wrap offers visibility or security. Both provide a strong cling, ensuring stable, damage-free shipments while meeting operational and aesthetic needs.

Secure your free sample of premium hand pallet wrap today by

completing a contact form.